The Pick/Pack Confirm by Container entry routine is used to confirm the picked order by carton number. It also facilitates the use of advance shipping notices (ASN) by recording all the information required.

Stock can be picked using a standard picking slip and then the picking slip is confirmed at the packing stage, carton by carton. Carton numbers (1 of 3, 2 of 3 etc.) will be created if at the Pack Confirmation stage TMSDS/PRT-LAB has the RF label print set. This Control File is only looked at for RF warehousing.

Containers are created as soon as a new container is entered for different picking slips.

This program determines if an item needs to access the following ways:

- Item in DSIM00P

- Barcode in DSIM00P

- TUN in WHSHP

Same product may have 3 different TUN codes, ordered from different suppliers, but treated as one and the same product from the Item Masterfile, through to order processing and warehousing.

When a TUN is identified, then the TUN’s carton quantity is used as the scanned qty

This option can make use of the REPACK function that currently exists in the RF functions. TMSWH/PCK-RPCK can be set to instruct this program WHE100 to allow auto repack to be activated.

Dispatch Stage 2 need not be used in environments where no dispatch staging area exists, that is, where scan pack is the last time a carton is handled. The Packer and Checker can be entered and when Confirm Container is selected the carton weight can be captured (TMSWH/ENT-WGHT determines when to input carton weights). When Complete Order is selected to complete the picking slip and invoice is produced. The RF Dispatch program (DSE108) caters for an additional option on TMSDS/PRT-INV which is Flag 4 to print invoice at scan pack time.

TMSDS/PRT-LAB can be set to instruct the label print program to print carton numbers when scanning takes place at Pack Confirmation time because these are normally only produced at Dispatch Confirmation. TMSDS/PRT-CON P = Pick Confirmation or A = Pack Confirmation

Consolidated invoices are catered for when determining a connote number which means there can be multiple invoices on the one delivery.

Customer specific programs can run at the time as scanning a product, if WHE100D is in TMSDS/WI-PGM. This is useful in instances such as printing labels at the time of scanning.

Purpose for a nominated zone allows for the carton only flag to be utilized for ‘singles only’. When a movement occurs to PAIN location we use the movement action of “C” to “P”. The issue at the moment is that it breaks a carton in the originating location to singles then transports it to PAIN.

The reason this is happening is the action type “P” retains the carton quantity. If moved as a carton then it would put it as a carton into PAIN, but the manufacturing process requires it to be singles.

Allows for utilising the scan/pack function via a RF device.

This example describes how to confirm picking and packing details by carton.

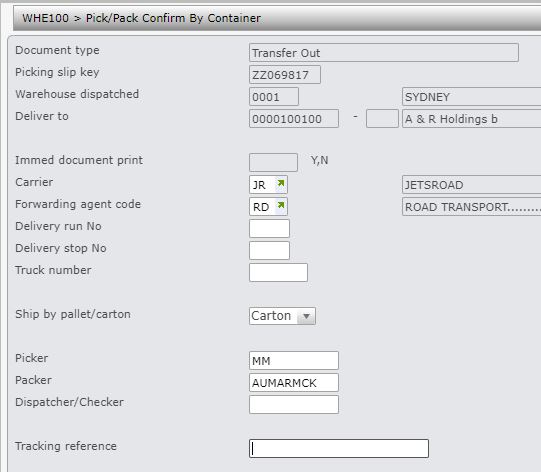

- In the menu, expand Base Modules > Distribution > Inventory Management > Warehouse Management > Warehouse Control > Pick/Pack/Dispatch Confirm> Pick Confirm and double-click WH Pick/Pack Confirm by Container. WHE100 Pick/Pack Confirm by Container selection panel appears.

| Field | Description |

| Picking date |

The date on which the picking was carried out. |

| Picking slip | The number of the picking slip you want to confirm. |

- Enter the valid picking slip number and click OK. WHE100 Pick/Pack Confirm by Container panel appears.

| Field | Description |

| Forwarding agent code | The forwarding agent code for the method used to deliver the goods. |

| Delivery run no | The delivery run number allocated to this order. For example, deliver in an overseas or a local courier run. |

| Delivery stop no | This number indicates the sequence in which goods are to be loaded onto the truck for that specific delivery run. |

| Truck number | An optional entry of the number of the truck that will be used in this delivery run. |

| Ship by pallet/carton | This defaults to C for Carton indicating that the titles will be shipped in cartons. This default can be overridden if required. Valid options are C=Carton or P=Pallet. |

| Picker | The name or user ID of the picker can be entered for inquiry purposes. This field can also be used to record the Consignment Note number or any other useful reference. The length of this field can be increased to 15 characters by setting a Control file accordingly. |

| Packer | Enter the Packers name or initials. |

| Dispatcher/Checker |

Enter the Dispatcher/Checker’s name or initials. |

| Tracking reference |

The name or user ID of the packer can be entered for inquiry purposes or any other useful reference can be entered. A tracking reference can be the proof of delivery number, in most cases the consignment note number, for a customer order. A Control File determines what this field is to be used for. A Consignment number per Carrier is recorded when the consignment number becomes known and the customer has received the goods. It can be viewed on the Transaction Header Inquiry screen. This is a 12 character field which determines whether to calculate a consignment note number automatically via TMSDS/EDI-CONN. |

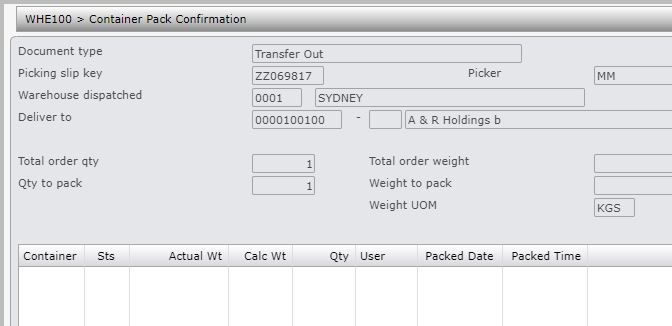

- Enter the required information and click OK to display panel used to record packing information.

| Function | Description |

| New container |

Access WHE100 Ctnr Pack to generate a new container number |

| Order inq |

Access WHM070 Original Documents Inquiry in inquiry mode to inquire on order details. For more information on this inquiry refer to the Warehouse Inquiries section of the manual |

| Complete order | This function completes the Title and quantity for a selected container, and will display the second screen, which has the options to view the picking slip transaction or access the Multi-location entry. |

| Option | Description |

| Select | Access WHE100 Ctnr Pack to generate a new container number. select in order to add another Title or change details against that container. |

| Detail | Access WHI130 Container Detail Inquiry to inquire on container details. Displays the status of a container. |

| Field | Description |

| Container |

Displays the container number scanned/entered. Options are available to continue packing into one of the existing containers or displaying the contents of the existing containers. There is a function on this screen to generate a new container. |

| Status | Status of the container P=Packed. |

| Weight | The actual and calculated weight of the packed containers. |

| Qty | The number of units packed into each container. |

| User | The user ID code that packed the goods into the container. |

| Packed date and time | The date and time the goods were packed into the containers. |

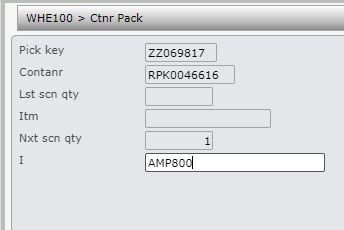

- Click function New container to open a new container. WHE100 Ctnr Pack panel appears.

| Function | Description |

| Confrm ctn | If you do not want to exit the only other option is to click Confirm carton. This function completes that Title and quantity for a selected container, and will display the second screen, this has the options to view the picking slip transaction or access the Multi-location entry. When all the quantities have been confirmed as correct for this carton, click Confirm container and the following screen displays to continue entering carton details for the picking slip Note: that the carton number details are updated regardless of whether labels are printed. |

| Chg nxt scn qty | Used to change the next scanned quantity if it is not 1. |

| Function | Description |

| Pick key | Defaults the picking key entered on the header screen. |

| Contanr | Defaults the container number entered on the previous screen |

| Lst scn qty | The first time this screen is displayed, there will be no last scanned quantity. Once a quantity has been entered or scanned and this screen is accessed again, a quantity will default to the last scanned/entered quantity for the last item scanned/entered. |

| ISBN | The ISBN that was last scanned will display. The first time this screen is displayed, there will be no last scanned ISBN. |

| Nxt scn qty | This quantity defaults to 1 however when a quantity greater than 1 is entered then that quantity is now displayed. Select Chg nxt scn qty to change the next scanned quantity if it is not 1. |

| ISBN | This is the next ISBN to be placed in this particular carton or container. Press <ENTER> to confirm and the ISBN will move into the Last Scanned Title field. |

- Enter item and click OK. If any of the Titles are scanned or entered and the full ordered quantity has already been recorded as packed, the error message Scn qty >odr qty will display. The same screen will be refreshed displaying the previously entered last scanned quantity and the Title directly under the Lst Scan Qty field. Note: If the container is full use function New container to open a new container.

- As each item/quantity is entered/scanned the system will check if the item requires serial number tracking. If serial number tracking applies then the system will call WHM280 Item Serial Number Entry.

- Scan/enter the serial number for each item quantity. The system will check the entered serials numbers are in stock. Once the serial numbers/s are successfully entered the system will return to scan/enter next item/quantity and serial number/s.

- Once all the items are scanned/entered click Confrm ctn. A window pops up allowing the user to scan in the weight.

- Enter weight and click OK.

| Note | Header information is updated immediately to avoid losing it if pack confirmation is exited before completing whole picking slip. |