Contents

Introduction

Print on Demand (POD) is a printing technology within the standard publishing supply chain. IP1 has supported this level of use for many years by generating purchase orders to printing suppliers who utilize POD methods. The 2 methods that have been supported are:

- Order to Order: Each individual customer sales order generates its own purchase order to the printing supplier and the products are delivered directly to the customer by the printer.

- Purchase Planning: This method consolidates all the demand from the various customers for the different products and a purchase order is raised to the printer. The products are delivered to the publisher’s warehouse and sent to the customer by the publisher.

In both methods shipment invoice from the printer will be used to receive the stocks into the physical or drop ship warehouse, release the backorders, generate the customer sales invoice, and create a supplier invoice in the Accounts Payable system.

IP1 has now developed physical and digital supply chain within the IP1 system to enable publishers to combine their various supply chain models within the one operational enterprise process. The system has been enhanced to include additional methods of customer delivery for POD. One of these is distribution using in-house controlled POD and delivery:

- POD-PO products will be supplied utilising the existing order to order or the purchase planning process by raising a PO to the supplier.

- POD –direct products; with this method the products will be supplied and delivered directly by the POD printer without the need to raise a purchase order and receipting and dispatching in IP1. POD printer will be a component of the delivery chain. A set of rules decide which POD printer will deliver the POD-direct products. The rules can be defined via a combination of customer and product attributes.

Process flow

Business rules

The following business rules have to be set up for POD -PO and POD direct products. These business rules must be setup with support from Iptor IP1 consultants. It is critical to understand the setting of control files and how it works. Control files must be setup correctly for the system to operate as intended. Any changes to the control files setup should be addressed cautiously and in consultation with Iptor IP1 consultants.

| Control file | Description |

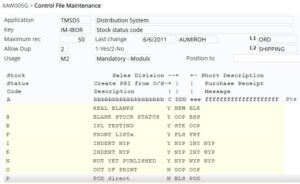

| TMSDS/IM-IBOR Stock status code | Define new stock status for POD-direct. Consider a separate Sales Division (TMSDS/TR-SDV) for POD sales analysis reporting.

|

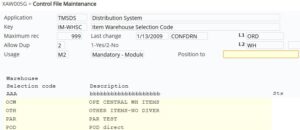

| TMSDS/IM-WHSC Warehouse selection code | Set up new warehouse selection code for POD. This will be used in TMSDS/WH-ORDD* setups to divert items to the dropship warehouse. Normally done based on POD stock status, but can also be set directly on item maintenance if this item is always to be handled by POD.

|

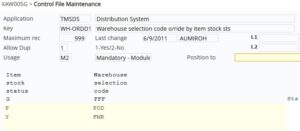

| TMSDS/WH-ORDD1 Warehouse selection code o/ride by item | Set up an entry for the POD item stock status ‘P’ with the POD warehouse selection code. This control file will allow the dynamic generation of the warehouse selection code for POD products based on the stock status.

|

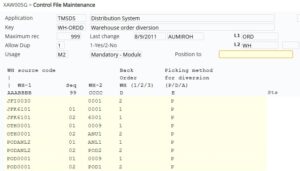

| TMSDS/WH-ORDD Warehouse order diversion | For the POD warehouse selection code and warehouse (WH-1); setup the warehouse order diversion to the dropship warehouse (WH-2).

|

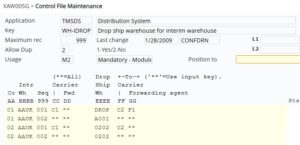

| TMDS/WH-IDROP Dropship warehouse for interim warehouse | If required, setup the interim warehouse in TMSDS/WH-IDROP to divert to dropship warehouse on pending release.

|

| TMSDS/SD-INV Supply direct invoicing rule | Setup the POD invoicing rule by company, i.e. define whether to wait for the POD products to be supplied before invoicing. |

The following control files are additional control files for POD direct products only.

| Control file | Description |

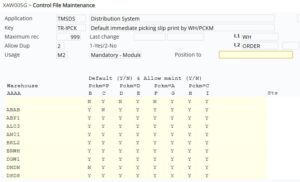

| TMSDS/TR-IPCK Default immediate picking slip print by WH/PCKM | For the dropship warehouse, set up the immediate picking to ‘Y’ for all picking methods. This is to allow immediate pick when POD direct products are split from normal physical products.

|

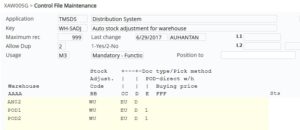

| TMSDS/WH-SADJ Auto stock adjustments for warehouse | Setup this control to flag the warehouse as a POD-direct warehouse; this will invoke another process to generate printing instructions to the POD printer. Stock Adjustment code must be setup to ‘Write up’ for POD-direct logical warehouse to automatically generate a stock write-up of the total quantity of the stocks to be invoiced.

|

The following control files must be setup with Vendor rules for the POD printer.

| Control file | Description |

| TMSDS/SD-VNT Supply direct:Vendor type | System defined control file holds the vendor type for POD printer. (2=POD printer) |

| TMSDS/SD-VNX Supply Direct: Vendor Code for web interface | Define the web interface vendor ID for the POD printer. |

| SD-VNDFT Supply direct:Vendor defaults | Set up the defaults for the POD printer by web interface vendor ID. |

| TMSDS/SD-VNMAP Supply Direct: Vendor mapping | Set up this control file to map the POD printer supplier code to the web interface vendor ID. It also has the rules of vendor acknowledgement of the printing instructions and the notification of product delivery for POD printers. |

| TMSDS/SD-SSTS Supply direct: Supply status | System defined control file; holds the status for directly supplied products tracking file. |

Other setup

| Setup task | Instructions |

| Setup POD titles | Create/setup POD titles with stock status = ‘P’ (DSM015 – Title masterfile) |

| Setup POD-PO supplier rules | Setup the supplier rules for POD-PO orders i.e. determine the printer based on a combination of customer and product attributes. (PUM030) via Database Management>Item Masterfiles>IM POD Supplier Rules. |

| Setup POD-Direct supplier rules | Setup supplier rules for POD-Direct orders i.e. determine the printer based on a combination of customer and product attributes. (DSM355) via Database Management>Item Masterfiles>Digital Product Distributor Rules. |

| Create dropship warehouse | Add new non-location control logical warehouse for the POD products. (WHW02O Logical Warehouse Maintenance) |

| Create interim warehouse | Create interim logical warehouse if required. (WHW02O Logical Warehouse Maintenance) |

Procedure

Print on Demand – Purchase Order (POD-PO)

POD-PO products are supplied using the order to order or the purchase planning process by raising a purchase order to the supplier (POD printer).

| Process | Instructions |

| Raise a sales order for POD PO products |

Note: To force the stock into backorder in the dropship warehouse regardless of stock availability in the main warehouse and dropship warehouse:

|

| Raise PO | When the order is at status ‘A’, the system will raise a PO to POD Printer (supplier). POD Printer is based on the POD supplier rules (setup in PUM030). |

| POD Printer to print | POD Printer will print products as per the PO and it will either dropship the order to the customer or deliver stock to publisher. |

| Delivery to publisher orders | Receive physical stock from POD printer into the backordered warehouse for delivery and invoice to the customer.

The system will release the backordered products from the relevant warehouse and dispatch to customer. |

| Dropship orders | Upon receipt of delivery confirmation from POD printer book the virtual stock into the backordered logical warehouse. |

| Invoice customer | Generate the customer invoice. |

Print on Demand – Direct

POD-Direct sales orders generate printing instructions to POD printer on order release and the products are delivered directly to the customer by the POD printer. There is no raising of purchase orders and receipting and dispatching of stock in IP1. POD printer will be a component of the delivery chain.

| Task | Instructions |

| Raise a sales order for POD Direct products |

On order entry the system will check TMSDS/WH-SADJ to determine if its POD direct warehouse and warehouse order diversion rules in TMSDS/WH-ORDD. Depending on TMSDS/WH-ORDD configuration, the system may supply items from normal physical stock warehouse first. Once that stock runs out, the system will automatically divert to supply from the dropship warehouse. As per the setting in TMSDS/WH-SADJ, the system will generate a stock write-up in the dropship warehouse for the unavailable quantity. |

| Generate print instructions | When the order is at status ‘A’, the system will issue printing instructions to the POD printer.(Web services should be setup for this). POD printer is based on the Digital Product Distr. group definition setup in DSM355.

Order can be invoiced if setup to invoice immediately as opposed to upon confirmation from POD printer. (This is configured in control file TMSDS/SD-INV). On receipt of the delivery instructions from the publisher, POD printer will print & send product to customer and send delivery confirmation/supplier invoice to the publisher. |

| Generate customer invoice | This step is automated if setup to invoice upon confirmation of delivery from POD printer. Web Services should be setup to send the delivery confirmation back to the publisher. |