Contents

Introduction

IP1 system allows serial number tracking for items that require serial numbers. All stock movements in and out of warehouses, e.g. receipts, sales, transfers and adjustments allow for serial numbers to be captured for each item/quantity. Item classifications in the system must be set up appropriately to allow serial number tracking on dispatch and receipt as required.

Serial numbers for Already delivered/charge only orders are captured during order entry since this picking method bypasses the warehouse process to capture serial numbers during pick, pack and dispatch process.

An order will pend with pending code ‘BX’ if serial numbers are missing for items in the order that require serial numbers.

View setup requirementsBusiness rules & item classification setup

The following business rules have to be setup to handle Serial number tracking. Business rules for Serial number tracking must be setup with support from Iptor IP1 consultants. It is critical to understand the setting of control files and how it works. Control files must be setup correctly for the system to operate as intended. Any changes to the control files setup should be addressed cautiously and in consultation with Iptor IP1 consultants.

| Note | This document does not cover customised setup tasks of specific companies. Deviations from this setup should be covered by setup tasks written by individual companies. |

| Business rules | Setup |

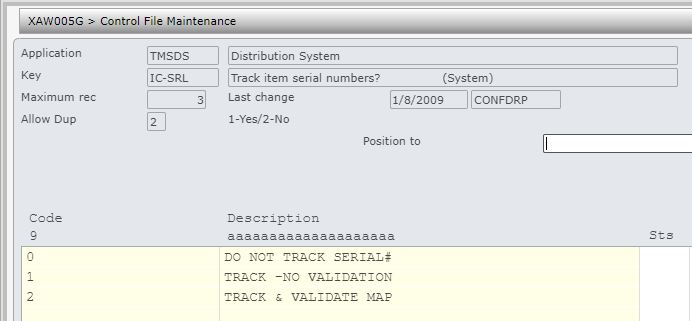

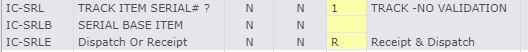

| TMSDS/IC-SRL Track Item Serial Numbers | This system defined control file is used to determine if an item is serial number controlled.

0 = serial number tracking is not required. 1 = track serial numbers without any validation on the serial number 2 = track serial numbers and validate against Warranty & Service serial number map file. (Warranty & Service feature that maintains serial number mapping is WSM210 – Serial number map maintenance). |

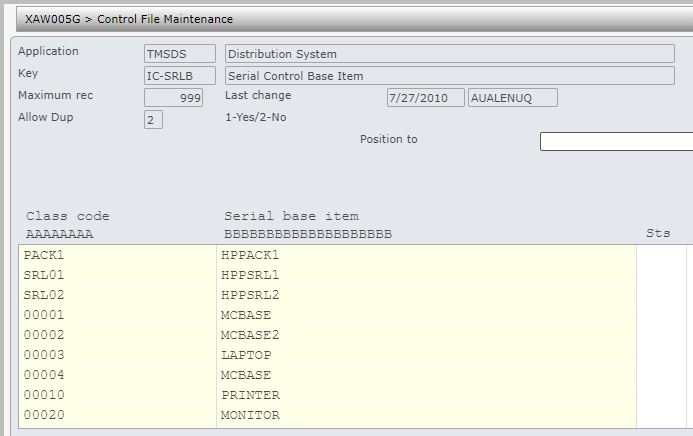

| TMSDS/IC-SRLB Serial Control Base Item | This control file holds all the valid serial base items used in serial number tracking. All serial controlled items that have a base item must have item classification IC-SRLB defined in Item master with one of the codes from this control file. |

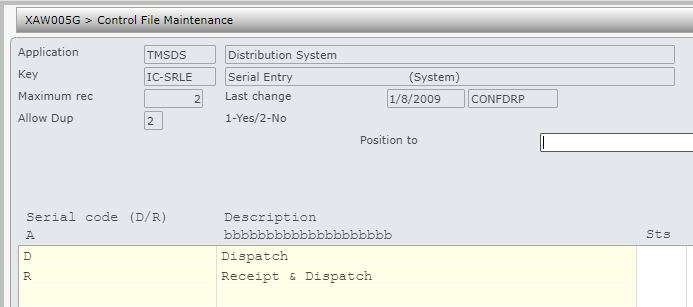

| TMSDS/IC-SRLE Serial Entry | This system defined control file determines when serial numbers are to be captured for items that are applicable for serial number tracking, i.e. at receipt and dispatch or just at dispatch time. A system wide default can be setup on TMSDS/ASRL-CLS to determine this. With the default setup there is no need to create IC-SRLE for individual items. |

| TMSDS/ASRL-CLS Serial Number Item Classification | This control file holds the following.

|

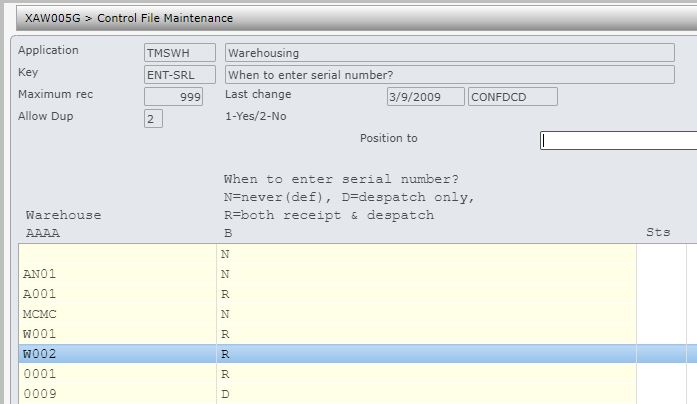

| TMSWH/ENT-SRL When to enter serial number? | This control file is used to validate the existence of serial numbers and when to validate. In dispatch only mode (D), only document type ‘A’ (invoice) will activate the serial number entry program. Blank warehouse code can be used as a ‘catch all’ default. |

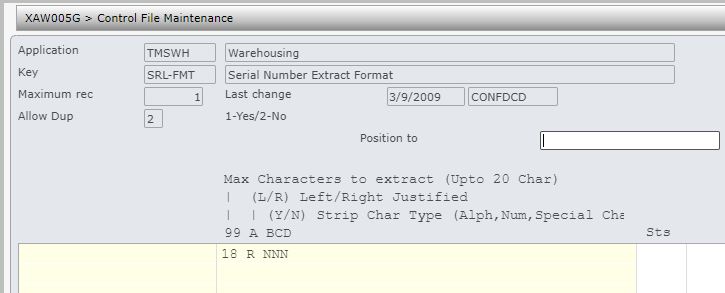

| TMSWH/SRL-FMT Serial Number Extract Format | This control file is used to format the serial number in Warranty & Service WHM275 Pallet Receipts by Model & Serial.

Max Characters to Extract – defines how many characters to extract. is has a maximum limit of 20 characters as the size of Serial number on our files is 20. Note : If entry is only 1 digit (say 8), then it should be entered as right justified (i.e. as 08). Left/Right Justified – whether to extract from Left or Right. Valid entries are ‘L’ or ‘R’. Strip Char Type: Whether to strip (exclude) alphabets(A-Z), numbers (0-9), Special characters (/*@+-%etc). Valid entries are ‘Y’ or ‘N’. |

The following Item classifications are for serial number tracking.

Procedure

It is your responsibility to ensure that you understand this procedure before performing the following tasks.

| Note | Deviations from this procedure should be covered by procedures written by your company. Before performing any tasks please ensure all the business rules are set-up accordingly. |

Serial number tracking

| Process | Steps | ||

| Orders – Already delivered/charge only | Serial numbers for Already delivered/charge only orders are captured during order entry since this picking method bypasses the warehouse process to capture serial numbers during pick, pack and dispatch process.

The system will check/apply the following for serial number tracking.

If the above conditions hold then WHM280 Serial Number Entry panel will appear for each item that requires serial number/s.

|

||

| Consignment transfers | Consignment transfer orders for serial controlled items are entered via Loan/C Entry/Issue (DSE005) and the serial numbers will be captured not during issue entry but in the WH pick/pack confirm by container process as explained in the next step. | ||

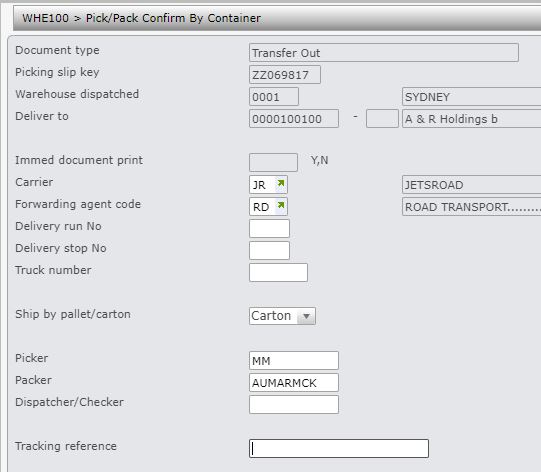

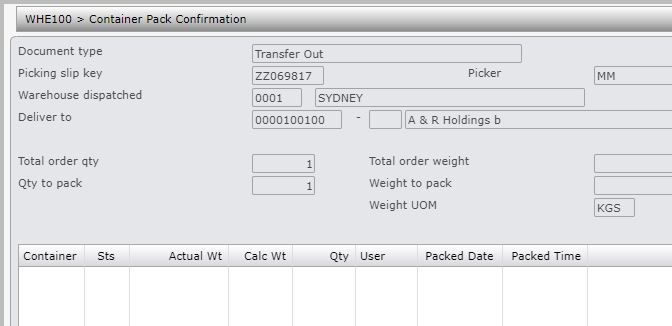

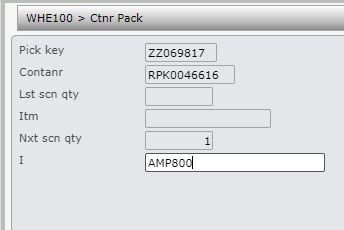

| WH pick/pack confirm by container | During Warehouse pick/pack confirm by container, the system will allow serial number entry for each individual item/quantity as it is scanned/keyed.

|

||

| Claims entry | During claims entry process, the system will check if the claim is for serial controlled items for non-location control warehouse. If so then it calls WHM280 Item Serial Number Entry program to capture the serial numbers. | ||

| Returns registrations | In Returns registration, if the serial number tracking is applicable then the system will capture serial number for each individual item/quantity just after it has been scanned. | ||

| Consignment returns | On consignment returns, the system will allow serial number entry for each returned item/quantity as it is scanned/keyed if the item requires serial number tracking..

|

||

| PO receiving/Shipping receipt entry (non-location control) | Serial numbers are captured in PO receiving & Shipping receipts entry via WHM280 Item Serial Number Entry. | ||

| View serial number history, stock inquiry & movements | Following inquiry programs are available for serial number tracking.

|